Aluminum Anodizing

The anodizing of aluminum is a popular process that improves the metal’s durability, resistance to corrosion and scratching.

Techmetals has over 50 years experience in titanium and aluminum anodize, assisting a variety of industries like the medical, aerospace and automotive fields for instance.

In addition to the reasons above, aluminum anodizing also offers some aesthetic benefits.

For example, it allows for a wide variety of colors to be added into to the part during the process. There is more about the adding of colors later.

Unlike other coatings that are adhere to a metal’s surface like a paint or plating, anodize actually interacts with the substrate. In other words, it literally BECOMES part of the metal itself!

In addition, anodizing is a chemical reaction (anodic oxidation) brought about by an electric charge. The reaction causes both penetration and buildup of the anodic oxide onto the surface of the metal. The general rule is 50% penetration and 50% growth, however different alloys sometimes offer slightly different results.

This process creates a hard, scratch-free metal that is perfect for use in extreme environments. The affordability and light weight of aluminum also makes this an attractive choice for plating.

"Pore" Some More

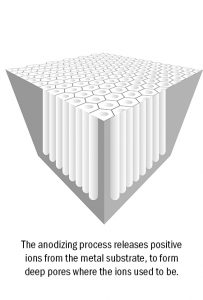

During the oxidizing process, ions release from the aluminum, forming deep pores like a honeycomb, into the base material. The longer the parts remain in the tank, the deeper the pores become.

During the oxidizing process, ions release from the aluminum, forming deep pores like a honeycomb, into the base material. The longer the parts remain in the tank, the deeper the pores become.

The end result is a pattern of open holes in the surface of the aluminum – which is also the reason anodize makes the material harder.

Typically, a depth 10 microns results in a coating that is very hard and scratch-resistant. Next, we seal the anodize simply by rinsing it with water or other chemicals, depending upon your needs. Also known as the “barrier layer”, this seal helps prevent further oxidizing on the metal’s surface.

Colors That Never Fade

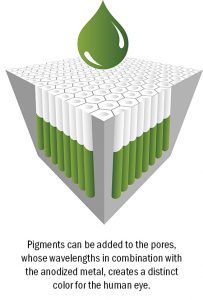

The amazing benefit to aluminum anodizing is that the pores created can also be filled with tinted pigments. As a result, you can easily add color to any of your parts.

The amazing benefit to aluminum anodizing is that the pores created can also be filled with tinted pigments. As a result, you can easily add color to any of your parts.

The dyes fill up to the pore surfaces, where they are permanently sealed off with the barrier layer. This creates a scratch-resistant color that cannot fade because it exists well below the surface of the metal. However, removing the color requires grinding the part down to the depth of the pores.

In addition, the concept of visible color really is the result of how the human eye perceives light reflecting off of the anodize. Different wavelengths of light cause our perceptions of color and shine.

Hard Coat, DEEP BLACK Anodizing Process (Type III)

Techmetals has developed a proprietary hard coat, DEEP BLACK anodizing process, darker than our standard black option. It is recognized by many of our customers to be the darkest black in the industry.

So if you need a part with extra dark, black hard coat anodize – be sure to request this process from our sales professionals.

Hard Coat Aluminum Anodizing (Type III)

To achieve greater corrosion protection for use in extreme environments or with moving, mechanical parts – the aluminum anodizing process can exceed depths > 10 microns.

As a result, this style of anodizing is also referred to as Type III or Hard Coat. The selection of hard coat anodize provides superior results, but also adds time and expense to the process.

Aluminum Anodizing Benefits:

Properties:

- Type II – Excellent Corrosion Protection

- Type III – Extremely Hard, Abrasion Resistant

- May be Selectively Plated

- Good Dielectric Qualities

- Economical

- A Number of Color Options Available

Specifications:

- MIL-A-8625 (Types II and III)

- AMS 2469

- AMS 2471

- Medical Validated Lines/Processes

- AMS 2472

- ASTM B 580

TYPICAL THICKNESS:

MIL-A-8625

— Type II: .0001-.001

— Type III: .0016-.0024

Can apply from .0001 – .0004 total thickness

CORROSION RESISTANCE:

>336 hours per ASTM B-117

DIELECTRIC RESISTANCE:

1000V per .001″ coating thickness

COLORS:

On-line dyes consist of black, red, blue, olive drab, tan, blue grey and others; specific dye colors available (call for more)

SEALS:

Hot Water Seal, Nickel Acetate, Sodium Dichromate

Techmetals Engineered Anodized Aluminum Finishes

In contrast to  standard hard coat, this rigid process delivers a Type III anodize finish that is not only more consistent — but also proven to outwear standard hard coat finishes.

standard hard coat, this rigid process delivers a Type III anodize finish that is not only more consistent — but also proven to outwear standard hard coat finishes.

The same superior hard coat anodize finish as OxyTech, with added lubricity.

The coating contains sub-micron particles of PTFE for added wear and lubricity.