PVD Coating / Thin Film

Physical Vapor Deposition – also known as PVD Coating or Thin Film – refers to a variety of deposition techniques where solid metal vaporizes in a high vacuum environment. Then it deposits on electrically conductive materials as a pure metal or alloy coating.

Since this is a “line of sight” process that transfers the coating material on a single atom or molecule level, it provides extremely pure and high performance coatings. So for many applications, PVD is much more preferable than electroplating. To this end, PVD coating is great for those products requiring thin film for a mechanical, optical, chemical or electronic function.

Additionally, these thin film finishes are also highly resistant to tarnishing. For this reason, they are perfect for a wide range of applications needing colors that do not fade. When applied to a base metal, PVD coatings provide hard, wear-resistant surfaces that don’t interact with the materials they cover. Therefore, it dramatically reduces friction and prolongs the life of the part.

Similarly, this is an environmentally friendly process that greatly reduces the amount of toxic substances disposed of when compared with more conventional types of coating involving fluid precursors and chemical reactions.

Techmetals offers roughly 26 different PVD options, including DLC coating – perfect for use with medical equipment and firearm production for example. We offer certifications for Nadcap Chemical Processing, Nadcap Coatings, ISO 9001:2015, ISO 13485:2016, AS9100D, FAA, ITAR, as well as validated processes for the medical industry.

Benefits of PVD Coating:

- Reduction of friction

- Improved lubricity

- Abrasion & wear resistance

- Improved speeds & feeds on cutting tools

- Better release of plastic parts

- Less galling & die polishing

- Reduces downtime

Specifications:

AMS 2444

PVD Coating / Thin Film Options

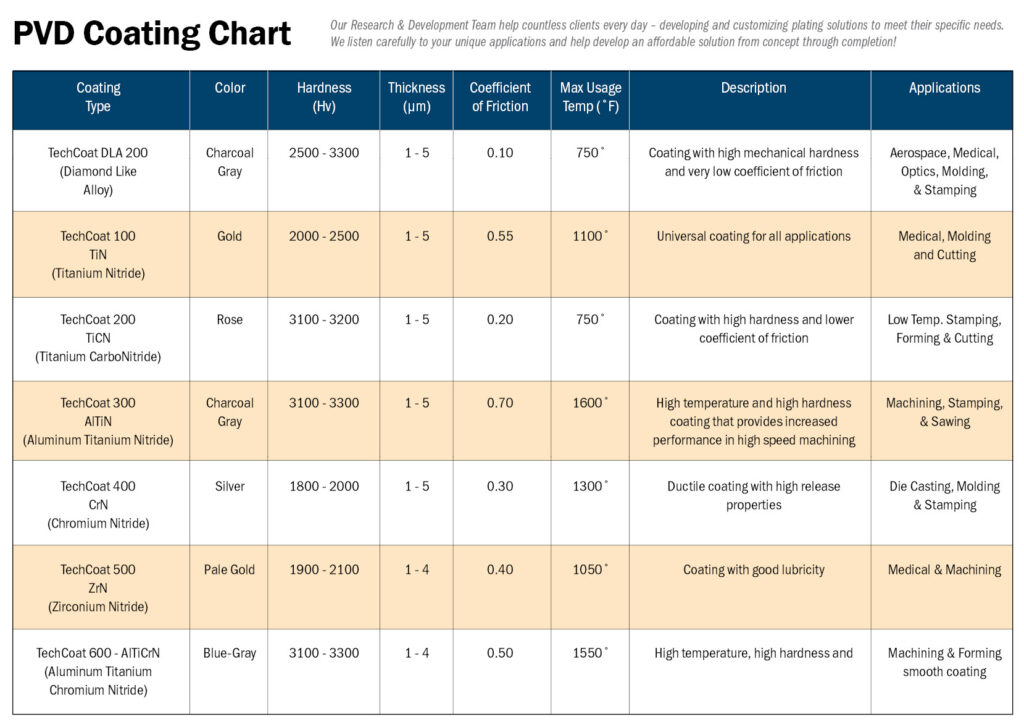

TechCoat Engineered PVD

Techmetals has available some specialized PVD solutions in their TechCoat line — offering the highest quality and meeting the most exacting standards. Check the options below for more on each of these unique combinations.

TechCoat 100 is a proprietary general purpose coating providing universal improvement for most wear applications. Used within the medical, molding and cutting industries.

TechCoat 100 is a proprietary general purpose coating providing universal improvement for most wear applications. Used within the medical, molding and cutting industries.

- Medically Validated

- Environmentally Friendly Technology

- Chemical Inertness

- Minimizes Additional Processes

- Reduction of Lubricants

- Wear Protection

TechCoat-Med 100 is a proprietary titanium rich coating providing excellent performance for medical tools and implants. Sample uses include the production of joint components, implants and other medical instruments.

TechCoat-Med 100 is a proprietary titanium rich coating providing excellent performance for medical tools and implants. Sample uses include the production of joint components, implants and other medical instruments.

- Medically Validated

- Environmentally

- Friendly Technology

- Biocompatibility

- Wear Protection

TechCoat DLA is a proprietary Diamond Like, DLC coating series utilizing the latest coating technology to provide an extremely effective solution for high wear, high friction and surface roughness problems. Industries utilized include: aerospace, automotive, medical, optics, injection molding, die casting and more.

TechCoat DLA is a proprietary Diamond Like, DLC coating series utilizing the latest coating technology to provide an extremely effective solution for high wear, high friction and surface roughness problems. Industries utilized include: aerospace, automotive, medical, optics, injection molding, die casting and more.

- Medically Validated

- Very Low Coefficient of Friction

- High Mechanical Hardness

- Chemical Inertness

- Optical Transparency

- Reduces Additional Processes

- Environmentally Friendly Technology

- Reduction or Elimination of Lubricants

- Low Process Temperature for Sensitive Parts

- High Wear Protection

TechCoat 200 is a proprietary hard purpose coating with a low coefficient of friction. Industries utilize in low-temperature applications for stamping, forming and cutting.

TechCoat 200 is a proprietary hard purpose coating with a low coefficient of friction. Industries utilize in low-temperature applications for stamping, forming and cutting.

- Medically Validated

- Environmentally Friendly Technology

- Extreme Mechanical Hardness

- Reduction of Lubricants

- Wear Protection

- High Edge Stability

TechCoat 300 is a proprietary high-temperature, high hardness coating provides increased performance for high-speed machining, stamping and sawing applications.

TechCoat 300 is a proprietary high-temperature, high hardness coating provides increased performance for high-speed machining, stamping and sawing applications.

- Environmentally Friendly Technology

- Extreme Mechanical Hardness

- Reduction of Lubricants

- Superior Heat Resistance

- Elevated machining

- Medically Validated

- Environmentally Friendly Technology

- High Mechanical Hardness

- Reduction of Lubricants

- Optimal mold release properties

- Low deposition temperatures

- Corrosion protection

TechCoat 500 is a proprietary high performance coating with great lubricity. It provides increased performance within the medical and machining industries.

TechCoat 500 is a proprietary high performance coating with great lubricity. It provides increased performance within the medical and machining industries.

- Environmentally Friendly Technology

- Biocompatible

- Corrosion Resistant

- High Heat Resistance

- Optimum Release for Forming Applications